Electroplating sets and accessories for multiple applications

Advantages of electroplating

- Independent electroplating

- Coating of metallic surfaces

- Detailed application instructions

- Ready-to-use electroplating sets

- Various procedures

- Free customer advice

Finish metal surfaces yourself

Cost-effective electroplating for private and commercial customers

Detailed advice on your projects

The journey is the reward – the right procedure for a perfect coating result

- Pre-treatment: the better the pre-treatment, the better the coating result (applies to every coating step). This includes a grease- and dust-free surface as well as a smooth polish.

- Electroplating: no errors should occur during the process. Here it depends on the choice of the right electrolyte and the corresponding correct settings on the power supply unit. Details can be found under the respective products.

- After-treatment: At the end, the object should be polished, cleaned and, if necessary, degreased again.

Frequently asked questions

You have to multiply the current density recommended for the respective electrolyte by the surface area of the workpiece in dm² and then get the required current intensity. The voltage will readjust when the current is set accordingly.

This varies from electrolyte to electrolyte. If the anodes are made of the same material as the salt in the electrolyte solution (e.g. copper, nickel, silver, zinc), the salt content remains constant because the anode dissolves slowly but steadily. However, the electrolyte is still contaminated at some point and brighteners (if present) are used up.

Certain electrolytes can be diluted. The gold electrolytes Flash and Midas can be diluted in a ratio of up to 1:1. However, the speed of deposition and the shine then decrease rapidly.

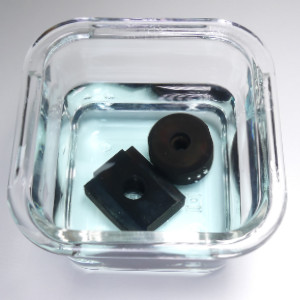

The anodes should be at least as large as the surface of the object to be coated. The supply of 2 anodes (left and right) has been proven to give better results.

If you want to coat from both sides at the same time, you should place an anode in the tank on each side and place the workpiece in the middle. The deposition is then more uniform than with the method with only one anode.

The depletion of the electrolyte can be recognised by the slowing deposition. The colouring of the gold electrolyte Midas, for example, does not indicate that the electrolyte has been used up.

For gold and palladium: stainless steel or graphite. For copper (basic and acidic): Copper. For nickel electrolyte: nickel. For silver electrolyte: silver. For zinc electrolyte: zinc. For chrome electrolyte: not compatible with bath electroplating.

No, unfortunately that is not possible. Our chrome electrolyte only works in conjunction with the brush process (tampon electroplating).

.jpg)